Water is siphoned from the tank shown: this phenomenon takes center stage as we delve into the intriguing world of fluid dynamics. In this exploration, we will unravel the principles governing siphoning, uncover its diverse applications, and provide practical guidance for designing and troubleshooting effective siphoning systems.

Prepare to immerse yourself in a comprehensive journey that illuminates the intricacies of this fascinating process.

Physics of Siphoning

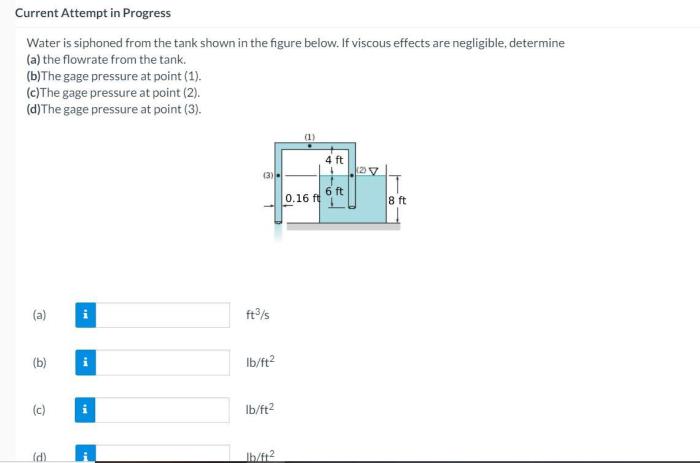

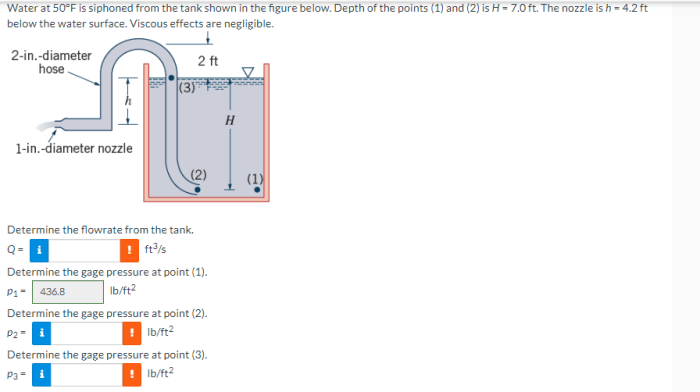

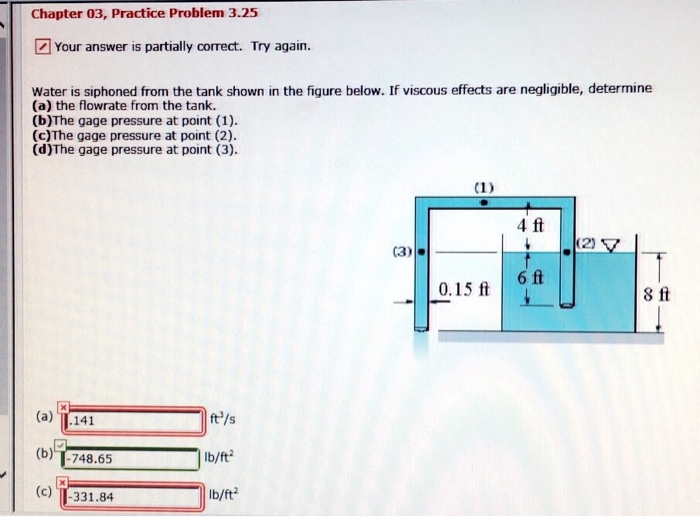

Siphoning is a process that utilizes atmospheric pressure to transfer a liquid from a higher reservoir to a lower one through a tube. The principle behind siphoning is based on the concept of pressure difference. When a tube is filled with liquid and one end is submerged in a liquid reservoir, the weight of the liquid in the tube creates a pressure at the bottom of the tube.

This pressure, known as hydrostatic pressure, is proportional to the height of the liquid column. If the other end of the tube is open to the atmosphere, the atmospheric pressure acts on the surface of the liquid in the reservoir, creating an upward force.

When the hydrostatic pressure at the bottom of the tube exceeds the atmospheric pressure, the liquid starts to flow out of the tube, creating a siphon.

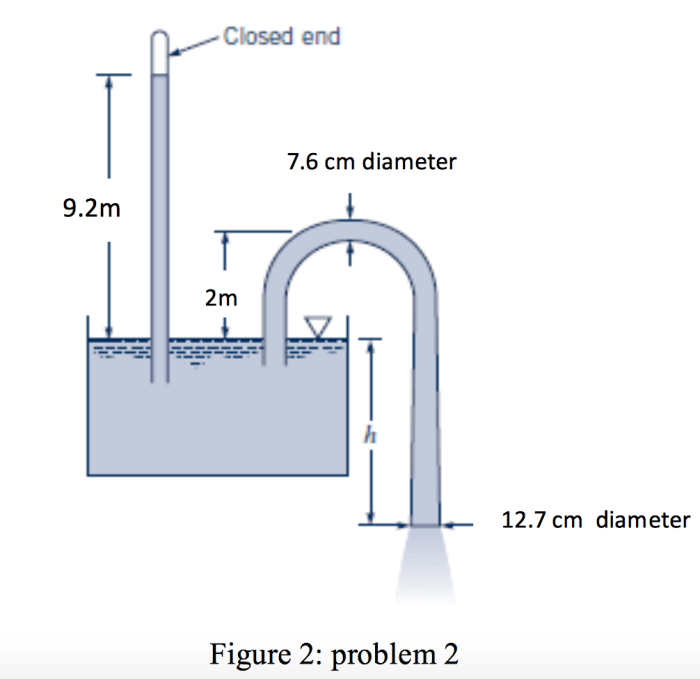

The rate of siphoning is influenced by several factors, including the height difference between the two reservoirs, the diameter of the tube, the length of the tube, and the viscosity of the liquid. A greater height difference results in a higher hydrostatic pressure, leading to a faster flow rate.

A wider tube allows for a larger volume of liquid to flow through, also increasing the flow rate. A shorter tube reduces the frictional resistance encountered by the liquid, further enhancing the flow rate. Finally, the viscosity of the liquid plays a role, with less viscous liquids flowing more easily than viscous ones.

Applications of Siphoning

Siphoning has numerous applications in various industries and everyday situations. In industrial settings, siphoning is used for transferring liquids from one container to another, such as in chemical processing, food processing, and water treatment plants. It is also employed in laboratory settings for transferring liquids between beakers, flasks, and other containers.

In everyday life, siphoning finds use in tasks like draining water from aquariums, removing fuel from vehicles, and transferring wine from barrels to bottles.

The benefits of using siphoning include its simplicity, low cost, and ability to transfer liquids without the need for pumps or other mechanical devices. However, siphoning also has limitations, such as the requirement for a height difference between the two reservoirs and the potential for leaks or spills if the tube is not properly sealed.

Design Considerations for Siphoning Systems

Effective siphoning systems require careful design considerations to ensure optimal performance. The diameter of the tube should be large enough to allow for a sufficient flow rate, while the length of the tube should be kept as short as possible to minimize frictional resistance.

The placement of the tube should ensure that the liquid flows smoothly without any bends or kinks that could impede the flow. Additionally, factors such as pressure, flow rate, and fluid properties should be taken into account when designing siphoning systems.

Troubleshooting Siphoning Issues: Water Is Siphoned From The Tank Shown

Siphoning systems can sometimes encounter issues that affect their performance. Common problems include slow flow rate, difficulty in priming the siphon, and leaks. Slow flow rate can be caused by a narrow tube, a long tube, or a viscous liquid.

Difficulty in priming the siphon may occur if there is air trapped in the tube or if the tube is not submerged deep enough into the liquid. Leaks can occur due to loose connections, cracks in the tube, or improper sealing.

To troubleshoot siphoning issues, it is important to identify the cause of the problem and implement appropriate solutions. For slow flow rate, the tube can be replaced with a wider one or shortened. To resolve priming issues, the tube should be completely filled with liquid and submerged deeply enough into the reservoir.

Leaks can be fixed by tightening connections, replacing damaged tubes, or using proper sealing materials.

Safety Precautions for Siphoning

Siphoning can involve potential hazards, particularly when dealing with hazardous or flammable liquids. It is crucial to take necessary safety precautions to minimize risks. When siphoning hazardous liquids, appropriate personal protective equipment, such as gloves, eye protection, and respirators, should be worn.

Flammable liquids should be siphoned in well-ventilated areas away from ignition sources. Additionally, it is important to avoid siphoning liquids that are too hot or corrosive, as these can damage the tube or cause injuries.

General Inquiries

What is the principle behind siphoning?

Siphoning is a process that utilizes atmospheric pressure to transfer liquids from a higher elevation to a lower one without the need for pumps or external energy input.

What factors affect the rate of siphoning?

The rate of siphoning is influenced by several factors, including the diameter and length of the siphon tube, the height difference between the liquid levels, and the viscosity and density of the liquid.

What are some common applications of siphoning?

Siphoning finds applications in various industries and everyday situations, such as draining aquariums, transferring fuel from vehicles, and removing excess water from flooded areas.

What safety precautions should be taken when siphoning?

When siphoning, it is crucial to avoid siphoning hazardous or flammable liquids, ensure proper ventilation, and be aware of potential spills or leaks.